A Beginner’s Guide to Double-Tee Shear Connections

In the realm of precast concrete construction, double-tee shear connections play a crucial role. This guide provides an overview relevant for beginners seeking to understand double-tee shear connections, their design, applications, and significance in structural engineering.

Understanding Double-Tee Shear Connections

Double-tee shear connections are integral parts of precast concrete systems. They facilitate load transfer between elements, ensuring stability and strength in structures. A double-tee is a specific form of precast concrete beam recognized for its distinctive shape, resembling a “T” when viewed in cross-section. This design enables the double-tee to efficiently span longer distances and bear substantial loads.

The Role of Shear Connections

Shear connections connect precast elements and help manage shear forces. These forces arise when loads are applied parallel to the connection plane, potentially leading to structural failure. A well-designed double-tee shear connection enhances the overall integrity of precast structures.

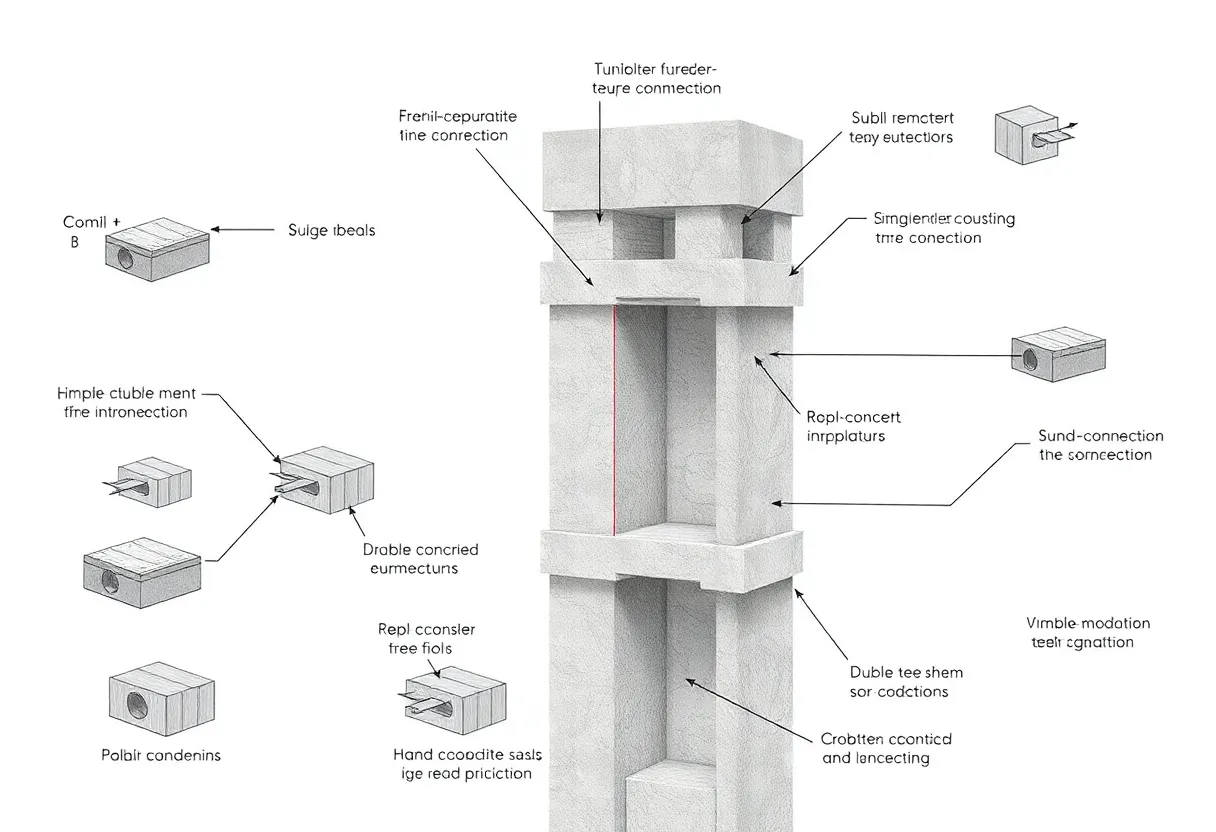

Types of Double-Tee Shear Connections

Double-tee shear connections can be categorized primarily into two types: moment connections and shear connections. Each type serves a unique purpose in construction and behavior under load.

1. Moment Connections

Moment connections are designed to resist bending moments in addition to shear forces. They provide a robust connection that allows for the transfer of both shear and moment between the double-tee elements. This type is essential in areas subject to significant lateral forces, such as seismic or wind loads.

2. Shear Connections

Shear connections are focused primarily on transferring shear forces without resisting moments. These connections typically allow for some rotation between elements. This is sufficient in scenarios where bending moments are minimal or non-existent. They’re commonly used in simpler structures where lateral forces are not a concern.

Design Considerations for Double-Tee Shear Connections

When designing double-tee shear connections, engineers must consider various factors to ensure safety, durability, and performance.

1. Load Conditions

The design must account for the types and magnitudes of loads that the connection will experience. This includes static loads from the building’s weight and dynamic loads from environmental factors.

2. Material Properties

Choosing appropriate materials is critical. Concrete strength, reinforcement type, and configuration directly influence connection performance. The use of high-strength concrete can enhance load-bearing capacity.

3. Connection Geometry

The shape and dimensions of shear connections also impact their effectiveness. Adequate width, depth, and angle of connection contribute to optimal load transfer capabilities.

4. Detailing for Constructability

Connection details must allow for easy assembly during the construction process. Engineers should provide clear and precise instructions for the placement of reinforcements and other connection components.

Common Applications of Double-Tee Shear Connections

Double-tee shear connections are prevalent in various construction scenarios, particularly in commercial and industrial buildings. They are commonly used in:

1. Parking Structures

Double-tee systems are ideal for parking garages due to their ability to span large areas without the need for numerous columns, maximizing available space.

2. Warehouse Facilities

The repetitive nature of double-tee elements lends itself well to warehouse constructions. They provide spacious interiors while meeting stringent durability requirements.

3. Retail Buildings

In retail construction, double-tee shear connections allow for open, adaptable floor plans that can accommodate evolving business needs.

Benefits of Using Double-Tee Shear Connections

The use of double-tee shear connections in precast concrete systems offers several advantages:

1. Speed of Construction

Utilizing precast elements, including double-tees, accelerates the construction timeline. Components can be fabricated off-site and assembled quickly on-site.

2. Cost Efficiency

Although initial costs can be higher for precast systems, savings can be realized through reduced labor costs and faster project completion. The overall lifecycle costs can also be lower due to reduced maintenance needs.

3. Design Flexibility

Double-tee connections allow for versatile structural designs. Engineers can create varying shapes and layouts to meet specific project requirements without compromising strength.

4. Improved Project Quality

Precast components can be manufactured under controlled conditions, leading to consistent quality and durability. This enhances the overall performance of the structure.

Challenges and Considerations

While double-tee shear connections present numerous benefits, they also pose challenges that engineers must navigate effectively.

1. Transport and Installation

Transporting precast elements to site can be complex, especially when dealing with large or heavy pieces. Proper planning is essential to ensure safe delivery and installation.

2. Connection Detailing

The connection detail is critical to the performance of double-tee shear connections. Inadequate details can lead to issues such as insufficient load transfer, which can compromise structural integrity.

3. Code Compliance

Double-tee shear connections must comply with building codes and standards, which can vary by jurisdiction. Engineers need to stay informed about these regulations to ensure compliance in their designs.

Conclusion

Double-tee shear connections are vital elements in precast concrete construction. Understanding their design and application is essential for engineers and builders alike. By focusing on load requirements, material selections, and connection detailing, professionals can create robust structures that meet contemporary building needs.

With the key advantages they offer in terms of speed, cost efficiency, and quality, double-tee shear connections will continue to be a popular choice in the world of structural engineering.